Off-ground Fire Fighting Flexible Tank

Our fire fighting flexible tanks are made with 1300 g/m² polyester coated fabric. The fabric is composed of a high tenacity polyester yarns framework and PVC coating. This structure gives very high resistance and an increased longevity. The fabric has an anti UV’s treatment and it is 100% recyclable. In the Off-ground system, the connection is done directly on a valve located on the fire fighting flexible tank. The installation of this flexible tank doesn’t request work permit or building permit. It is simple, quick and economical. Moreover it can be moved.

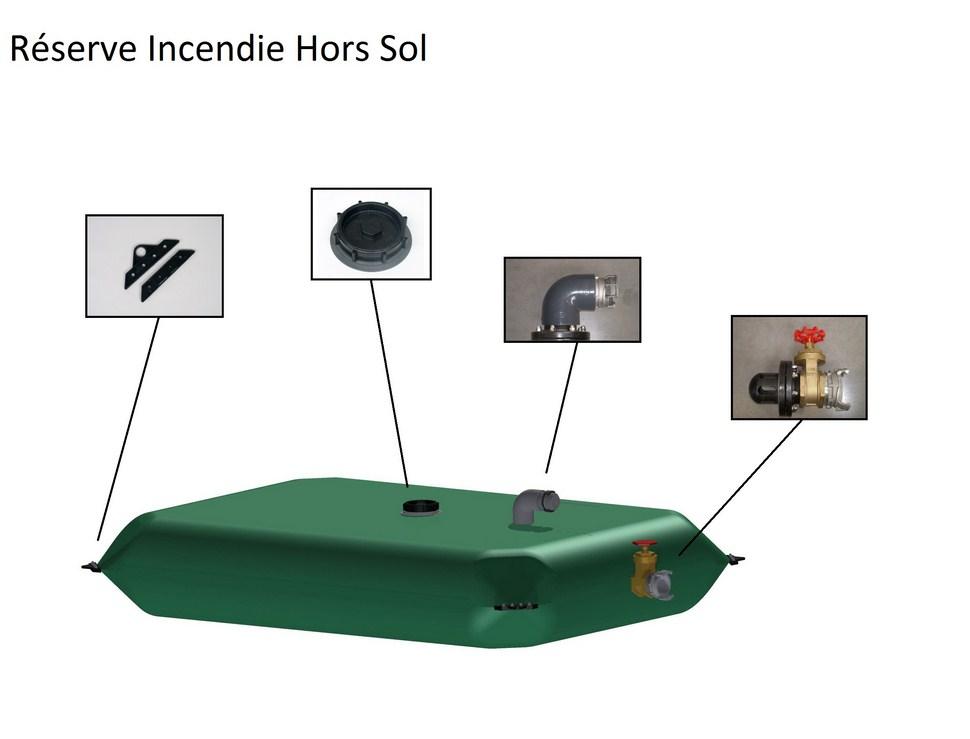

Pictures of off-ground fire fighting flexible tank

1300g/m² fabric

The fabric used to make fire fighting flexible tanks has a high tenacity polyester yarns framework covered by a PVC coating. Its weight reaches 1300 g/m². Technical Characteristics of the fabric : • weight : 1300 g/m² • framework : 2×110 dtex High Tenacity PES • Coating : PVC • Breaking strength (warp/weft) : 420/400 daN/5cm • Tearing strength (warp/weft) : 55/50 daN • Adhesion (warp/weft) : 12/12 daN/5cm • Temperatures of use : -30°C / +70°C • Color : green • Anti-UV treatment • 100% recyclable

The fabric used to make fire fighting flexible tanks has a high tenacity polyester yarns framework covered by a PVC coating. Its weight reaches 1300 g/m². Technical Characteristics of the fabric : • weight : 1300 g/m² • framework : 2×110 dtex High Tenacity PES • Coating : PVC • Breaking strength (warp/weft) : 420/400 daN/5cm • Tearing strength (warp/weft) : 55/50 daN • Adhesion (warp/weft) : 12/12 daN/5cm • Temperatures of use : -30°C / +70°C • Color : green • Anti-UV treatment • 100% recyclable

Equipments of the flexible tank

– 1 welded vent Ø146mm, – 1 DN 80 overflow + 1/2 symmetrical connexion + DSP 65 + cap, – 1 DN100 valve kit + antivortex + 1/2 DN100 symmetrical connexion, – 4 reinforced corners, – 1 repair kit, – thermal protection for the valve.

– 1 welded vent Ø146mm, – 1 DN 80 overflow + 1/2 symmetrical connexion + DSP 65 + cap, – 1 DN100 valve kit + antivortex + 1/2 DN100 symmetrical connexion, – 4 reinforced corners, – 1 repair kit, – thermal protection for the valve.

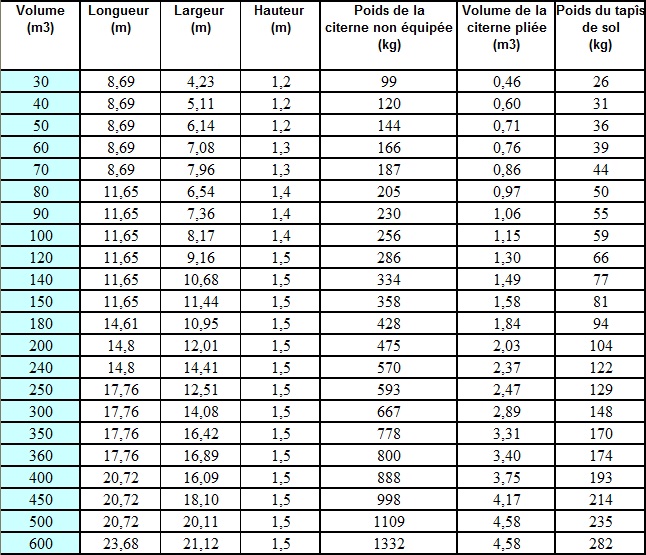

Volumes and dimensions of flexible tanks

Comments are closed.